AODD PUMPS

Hygienic Series

pharmaceutical, food and beverage, cosmetics

MAIN FEATURES

The DELLMECO ‘Hygienic Series’ are air diaphragm pumps specifically designed to meet the demands for the food, beverage, pharmaceutical and cosmetics industry.

Quick dismantling

The clamp system enables rapid dismantling without the need for tools.

Plain surface

The “sandwich” diaphragms has a plain surface which eliminates problems associated with microbial growth. The diaphragms are available in food grade material – pure TFM (PTFE).

Superior finish

Both the media side and outside are electro-polished to obtain a superior hygienic finish. Other special surface finishes may be carried out according to requirements.

Eco-air valve

The sealing system is lubrication-free, always keeping the unit and environment free from contamination

Variety of connection types

The pump is supplied as standard with connectors according to DIN 11851. However, it can be equipped with almost any type of connections used in the hygienic sector such as TriClamp, SMS, RJT, JIS or ANSI.

Pump designed for CIP and SIP system

Cleaning-In-Place (CIP) and Sterilisation-In-Place (SIP) are designed for automatic cleaning and disinfection without major dismantling of the pump.

360 VIEW

HOW TO INSTALL DELLMECO PUMPS?

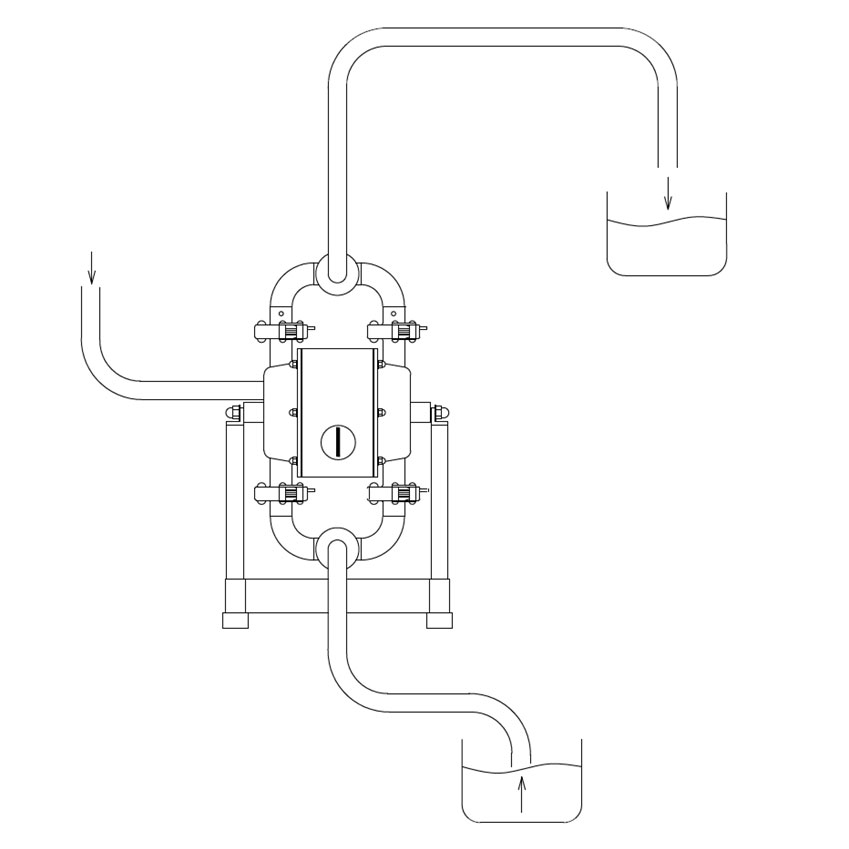

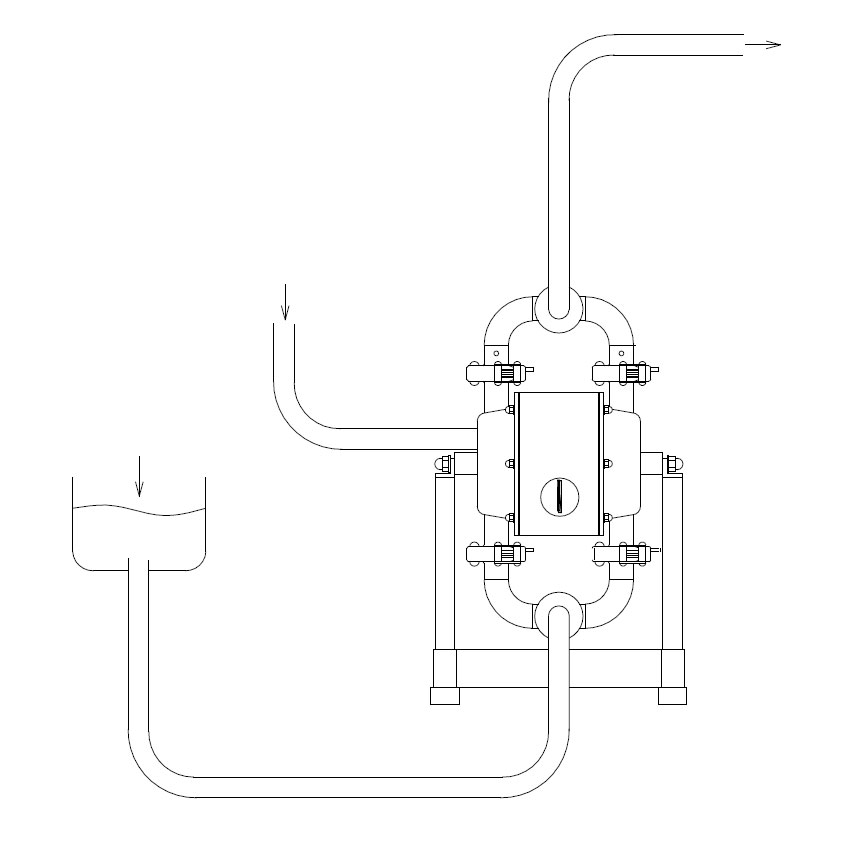

Self-Priming Application

The suction lift rangemis up to 8 meters. This will vary according to construction materials and application parameters. All data are based upon pumping water at 20°C

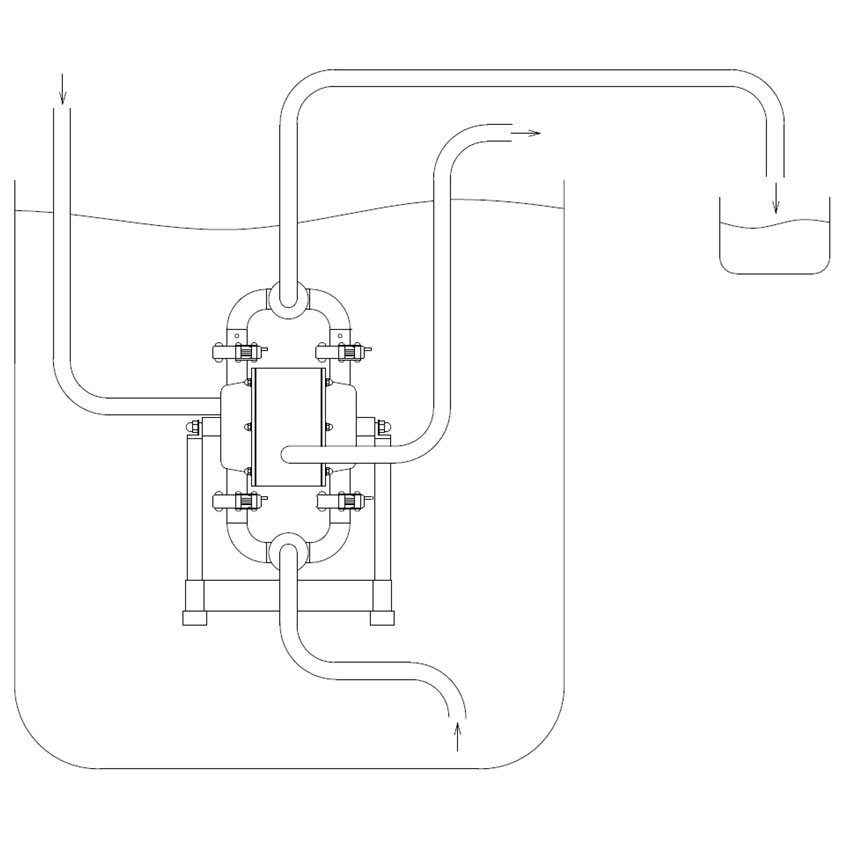

SUBMERGED OPERATION

Our pumps can operate under full submersion. The construction materials must be suitable for the surrounding liquid and the outlet must be positioned above the liquid level.

POSITIVE SUCTION HEAD

As a method for completely emptying holding tanks, clarifiers or similar containers. Optimum inlet pressure should be kept at 0.2-0.3 bar.

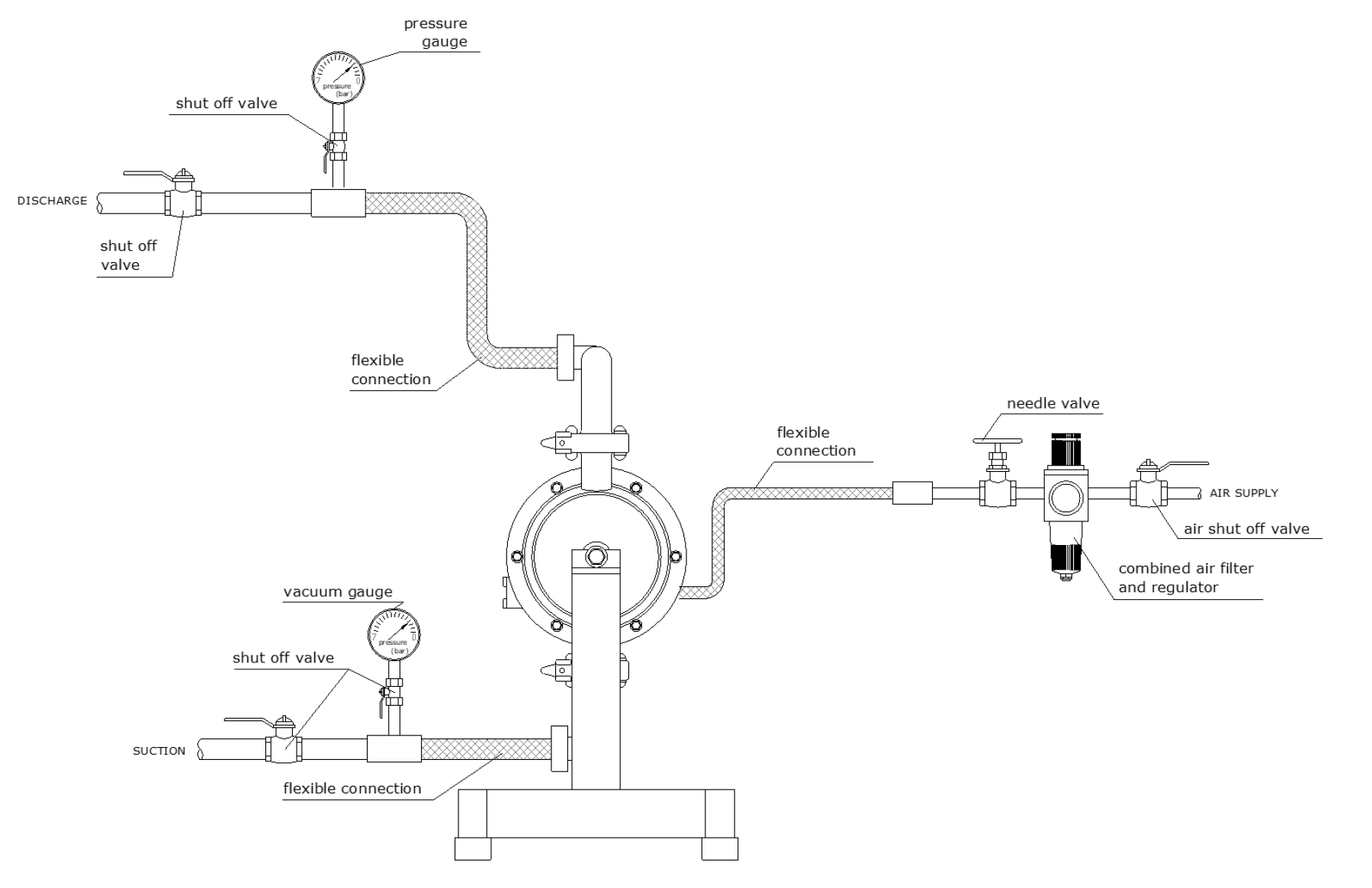

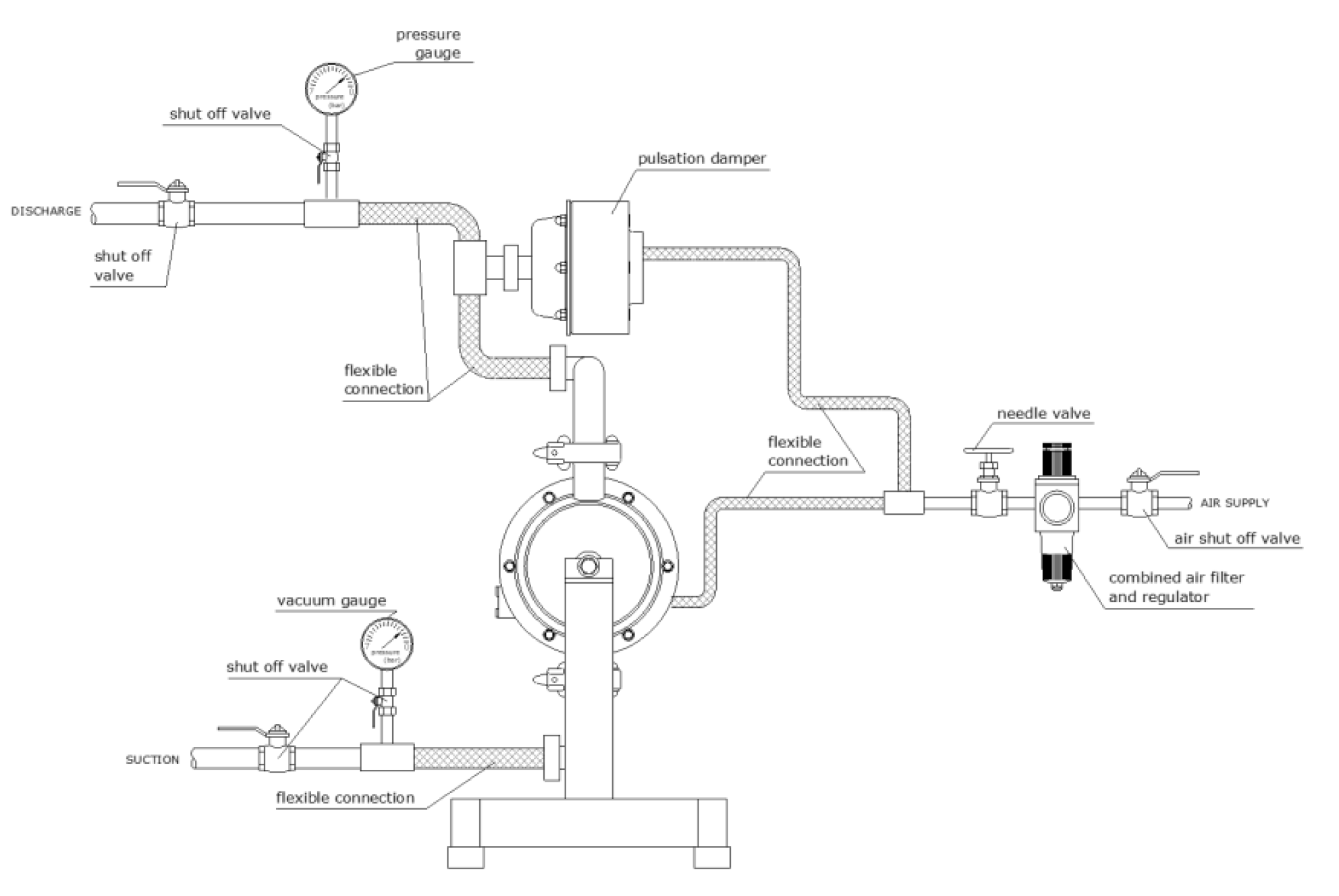

RECOMMENDED INSTALLATION GUIDELINES

To reduce piping and pump connections stresses, we recommend flexible connections on both the inlet and outlet pipes and air inlet connections. For best results DELLMECO recommends installing the pulsation dampener on the discharge side of the pump.

Without pulsation dampeners

With pulsation dampeners

1) Connect a flow valve and drain valve to the fluid discharge port of the pump.

2) Connect a valve for maintenance to the fluid suction intake port of the pump.

3) Connect a hose to the valve on the suction-port side and the valve of the discharge-port side of the pump.

4) Connect a hose on the suction-side intake and the discharge-port side to the respective vessels.

SPECIAL VERSIONS

Pump trolley

Heating / cooling jacket

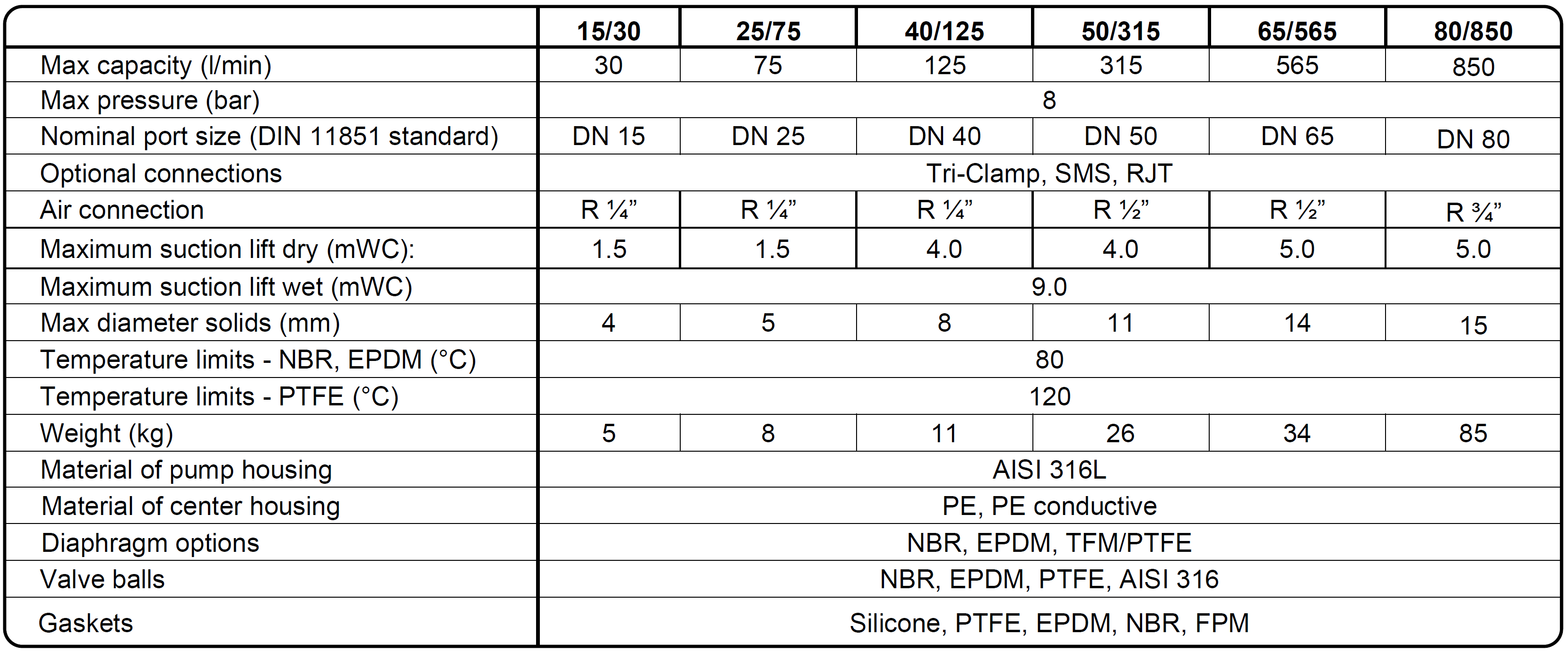

HYGIENIC TECHNICAL DATA

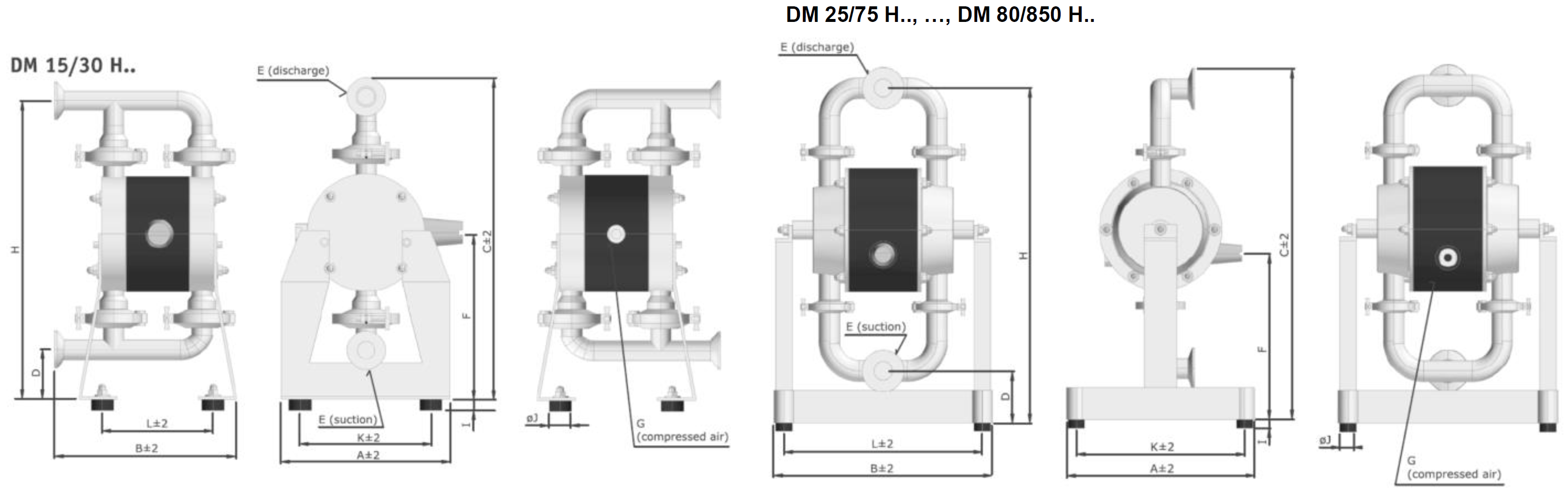

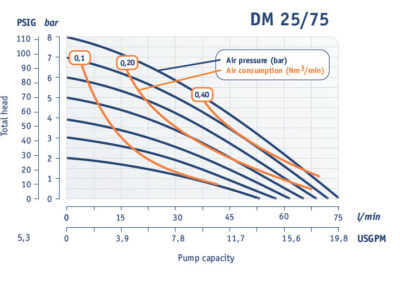

HYGIENIC PUMP DIMENSIONS

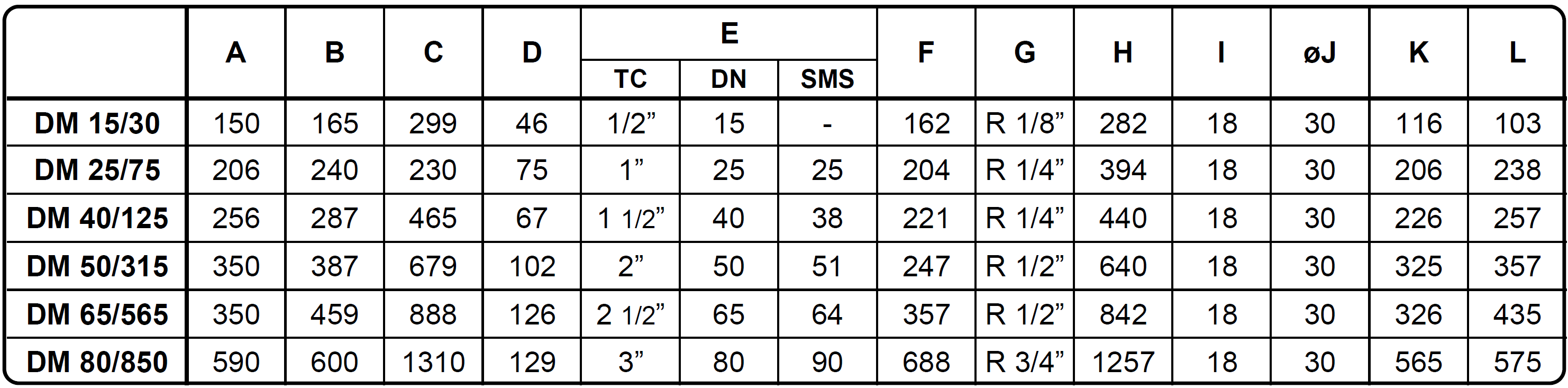

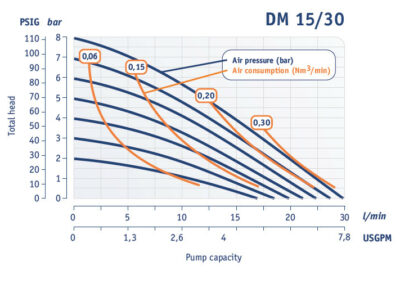

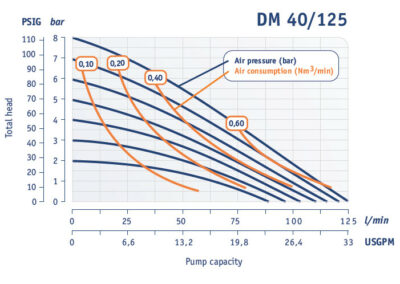

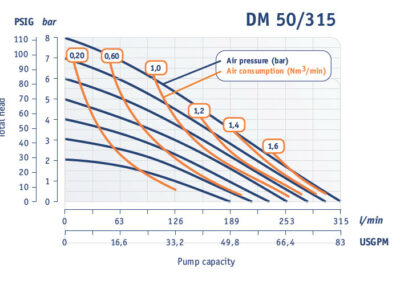

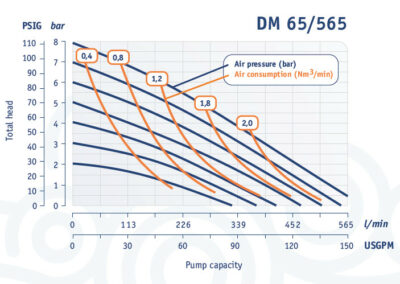

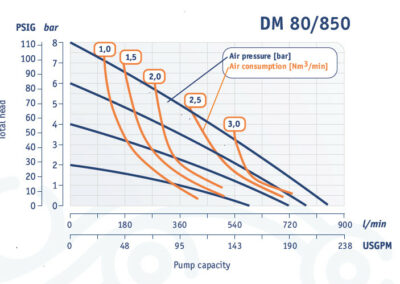

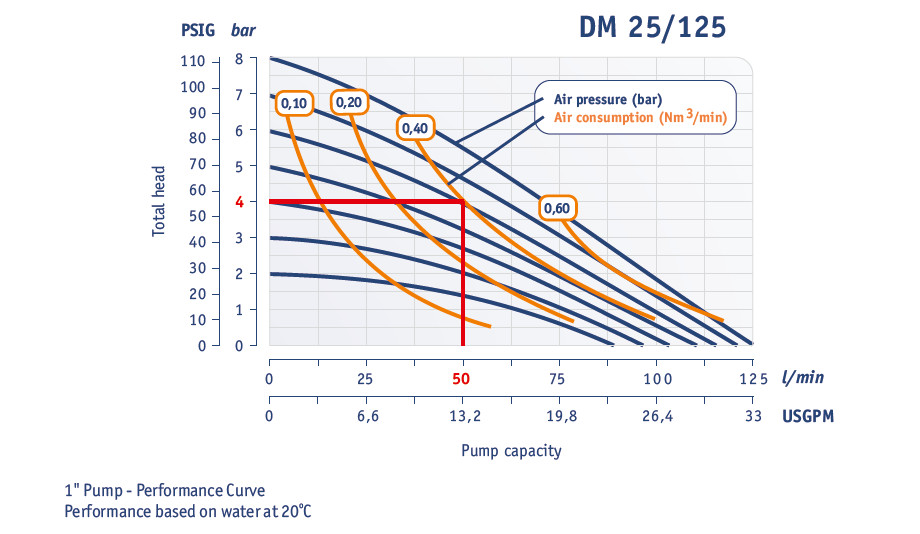

HYGIENIC PUMP CAPACITY

HOW TO SELECT THE PUMP SIZE

1. Enter flow rate and pressure. (example: 50 l/min and 4 bar)

2. Read off the approximate energy requirements in Volume and Pressure. (example: 0.40 Nm3/min at 6 bar)